行业4.0and the Evolution of Semiconductor Manufacturing

Semiconductor manufacturing is becoming increasingly competitive as significant investments in capital equipment are required to meet consumer demand for higher performing devices with greater functionality. To boost their competitiveness, chip makers are adopting Industry 4.0 manufacturing techniques to achieve higher levels of operational excellence. In this blog, I explain Industry 4.0, provide examples of its use in the semiconductor fab environment and how Applied Materials is enabling this evolution.

Before we go into details, let us understand what Industry 4.0 is. The concept of行业4.0was first coined by the German government to describe the fourth industrial revolution enabled by new technologies like artificial intelligence (AI), big data, cloud computing and the Industrial Internet of Things (IIoT). The first industrial revolution was powered by the use of steam and water power, the second by the use of electricity and the third through computerization (figure 1).

实施行业4.0概念将智能制造带入工厂运营。

Key characteristics of Industry 4.0 are:

- 制造系统的垂直整合

- 在工厂中,具有网络连通性的生产系统称为网络物理生产系统(CPP)。使用工业4.0,CPP是整合并垂直接口的,因此环境和价值链中的任何变化都反映在制造过程中。

- 整个企业和价值链的水平集成

- Integrating manufacturing units horizontally into the value chain along with partners, suppliers, sub-cons, etc.

- Enabling and accelerating the integrations through next-generation technologies like cloud, big data, mobility and AI/analytics

首先,让我们考虑半导体工厂的垂直整合。如下所示,这涉及整合所有ISA-95级别。

The ISA-95 levels span Level 0 for the physical equipment with all the sensors and actuators up to Level 4, which covers the enterprise business systems. Vertical integration at each level requires standardization of interfaces. In the semiconductor industry, equipment integration was standardized on the SECS/GEM interface quite some time ago. The high-speed SECS Message Service (HSMS) was established to support SECS/GEM communications via higher speed Ethernet. With the increased use of sensors, semiconductor equipment is now capable of transmitting high volumes of engineering data.

In order to support high-speed diagnostic data collection, the engineering data interface, now called Interface-A, has been separated from the control interfaces and is used only for gathering equipment data. This meets the industry needs to have all of this data on a common platform for consistency and easy integration/analysis. The result is increased effectiveness of various analytic solutions like run-to-run (R2R) control and fault detection and classification (FDC) analysis, which are available as part of Applied’sSmartFactory®manufacturing solutions.

下一个集成级别是生产执行/控制,WIP(工作中)管理和物流。根据行业4.0的数据,产品(将其视为晶圆厂中的产品)是CPS(网络物理系统),并且足够聪明,可以知道它们是什么,将成为什么产品以及需要去的地方。他们可以直接与同样聪明的CPP进行沟通。但是,在当前的半导体FAB环境中,产品和设备不够智能。

同样,在制造操作中,目前存在于MES(制造执行系统)中,该系统在路线,操作等方面具有信息。调度和调度通过智能,分析解决方案(实时分配和调度解决方案)进行了优化。当产品/地段(CPS)和设备(CPP)变得智能(通过AI)时,MES,调度和调度解决方案将在逻辑上更加偏心。MES,调度和调度解决方案是Applied的SmartFactory®投资组合的核心部分。

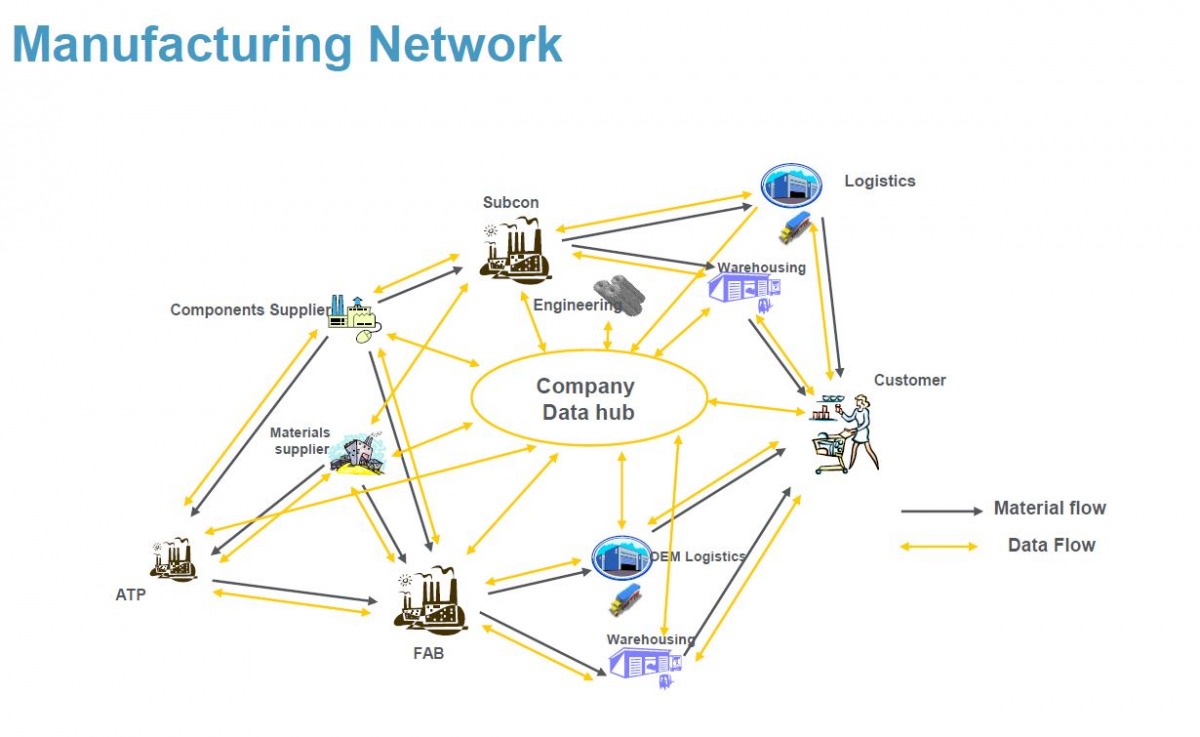

Let us now look at the horizontal integration within the semiconductor manufacturing network.

当前,半导体值链有些顺序。晶圆厂的大量/晶圆进入晶圆银行进行组装,测试和包装,然后进入仓库,然后才被运送到OEM。这种情况正在改变;制造业正变得越来越类似网络,晶圆厂和包装工厂是网络中的节点(如图3所示)。

根据行业4.0原则,我们需要建立一个协作和智能网络。以消费者为中心和需求驱动的制造业正在推动制造网络分配和协作的需求。实现这一目标的一种方法是将一个称为“虚拟工厂”的制造企业平台,我们可以将不同的工厂,合作伙伴和供应商集成到一个平台上。这可以通过云计算,IIOT和大数据等新兴技术来实现和加快。

Applied做出了许多发展,以使半导体晶圆厂能够朝着工业4.0迈进,尤其是从垂直整合的角度来看。各种制造解决方案,例如我们智能MES而且我们的计划/调度/调度解决方案使Fabs更加敏捷和灵活。

In the future, the process operations of a fab can be further transformed through AI. Fabs will become more of an environment where CPPS equipment fulfills requirements or demand from CPS lots through direct and intelligent communication. Manufacturing software like MES will become logically de-centralized making sure that operations comply with rules/regulations. In upcoming blogs, I’ll continue to discuss the benefits and challenges of Industry 4.0 in the semiconductor industry, as well as MES for Industry 4.0 (MES 4.0).

Want to join the discussion?

Add new comment:*

*Comments must adhere to our讨论指南和参与规则。